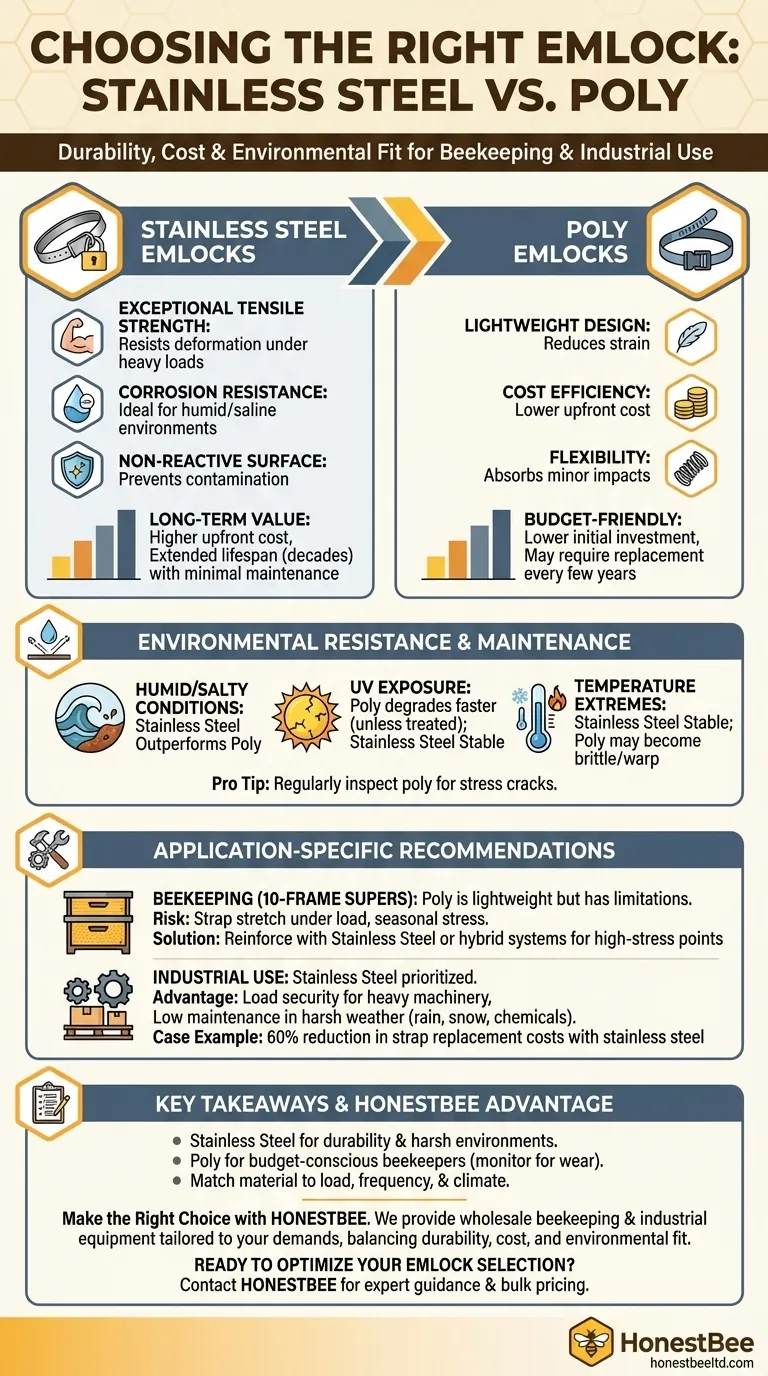

Selecting the right Emlock type—stainless steel or poly—can significantly impact the longevity and efficiency of your equipment. Whether you're a beekeeper managing 10-frame supers or an industrial user facing harsh weather conditions, understanding material properties, cost trade-offs, and environmental adaptability ensures optimal performance. Here’s how to match Emlock features to your specific use case.

Choosing Between Stainless Steel and Poly Emlocks

Key Features and Material Properties

Stainless Steel Emlocks are known for their:

- Exceptional tensile strength, resisting deformation under heavy loads

- Corrosion resistance, ideal for humid or saline environments

- Non-reactive surface, preventing contamination in sensitive applications

Poly Emlocks offer:

- Lightweight design, reducing strain during frequent handling

- Cost efficiency, often priced lower than metal alternatives

- Flexibility, absorbing minor impacts without cracking

Durability vs. Cost: Long-Term Value Analysis

While stainless steel Emlocks have a higher upfront cost, their extended lifespan (often decades with minimal maintenance) makes them cost-effective for intensive or long-term use. Poly Emlocks, though budget-friendly initially, may require replacement every few years in high-wear scenarios.

Example: For beekeepers inspecting hives weekly, poly straps might suffice, but industrial users moving heavy equipment daily will benefit from stainless steel’s resilience.

Environmental Resistance and Maintenance Requirements

- Humid/Salty Conditions: Stainless steel outperforms poly in coastal or chemically exposed areas.

- UV Exposure: Poly straps can degrade faster under constant sunlight unless treated with UV inhibitors.

- Temperature Extremes: Stainless steel remains stable in freezing or high-heat environments, while poly may become brittle or warp.

Pro Tip: Regularly inspect poly Emlocks for stress cracks, especially after temperature fluctuations.

Application-Specific Recommendations

Beekeeping and 10-Frame Supers: Poly Strap Limitations

For beekeepers, poly Emlocks are popular due to their lightweight handling. However, consider these caveats:

- Frame Weight: Poly straps can stretch over time when supporting fully drawn 10-frame supers, risking hive instability.

- Seasonal Stress: Frequent hive expansions in spring may accelerate wear.

Solution: Reinforce high-stress points with stainless steel Emlocks or hybrid systems (e.g., poly straps with metal corner locks).

Industrial Use: Stainless Steel’s Weatherproof Advantage

Industries like agriculture or construction should prioritize stainless steel for:

- Load Security: Ensures heavy machinery or palletized goods stay immobilized during transport.

- Low Maintenance: No need for frequent replacements, even in rain, snow, or chemical spills.

Case Example: A Midwest grain distributor reduced annual strap replacement costs by over 60% after switching to stainless steel Emlocks for outdoor silo straps.

Make the Right Choice with HONESTBEE

Whether you need the rugged reliability of stainless steel or the economical flexibility of poly Emlocks, HONESTBEE provides wholesale beekeeping and industrial equipment tailored to your demands. Our solutions help commercial apiaries and distributors balance durability, cost, and environmental fit—ensuring your operations run smoothly season after season.

Ready to optimize your Emlock selection? Contact HONESTBEE today for expert guidance and bulk pricing on high-performance strapping solutions.

Key Takeaways:

- Stainless steel excels in durability and harsh environments; ideal for industrial users.

- Poly straps suit budget-conscious beekeepers but require monitoring for wear.

- Match material properties to your specific load, frequency, and climate conditions.

By aligning Emlock type with your use case, you invest in efficiency, safety, and long-term savings.

图解指南

相关产品

- 用于养蜂的专业水滴式蜂箱把手

- HONESTBEE 专业长柄蜂巢工具(带精密切割刀片

- 用于养蜂的带安全锁扣的专业镀锌蜂巢带

- HONESTBEE 用于养蜂的先进人体工学不锈钢蜂巢工具

- 用于养蜂的专业刻字圆形蜂箱编号标签